MiniTec GmbH & Co. KG

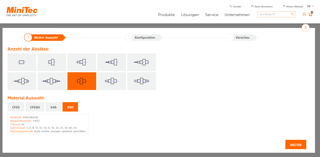

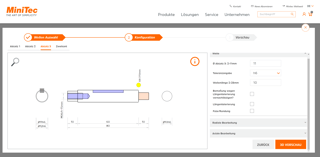

In the web store of MiniTec GmbH & Co. KG, customers can configure various linear components with the help of customX.

Linear technology performs central tasks in mechanical and plant engineering. Linear systems convert drive forces and provide movement. MiniTec, therefore, offers a wide range of products in the field of linear technology to match its modular profile system. In doing so, the supplier fulfills a general customer wish for a simple ordering process: Many linear components can be individually configured in the web store and inquired about directly. The "machine" in the background, the configurator from customX, generates all the documents required for production and merchandise management after the order has been placed.

Targets

The software was to fulfill the customer's wish to be able to configure products directly on the website and at the same time drive the optimization of internal processes. Operation was to be intuitive for the customer.

Implementation

customX was purchased, the employees were trained, the rulebook was then set up in-house. With the help of the specialists at customX, it was integrated with the other software systems. The products were then gradually documented in customX.

Conclusion

Ordering on the web is now very easy: the customer enters their requirements and can directly download the documents, which are automatically generated in the background. Customers reach their goal faster and the design department works more efficiently.

With customX to the perfect shaft

Many constructions in mechanical engineering only fulfill their actual function through linear technology. This begins with simple width, length or height adjustments and continues with devices for loading and unloading processes ("Pick & Place") and extends to measuring devices and multidimensionally operating gantry robots. MiniTec GmbH & Co. KG in Schönenberg-Kübelberg, Germany, is one of the specialists in this field. The medium-sized company employs around 420 experts at eleven locations in Germany and abroad and was identified as a "hidden champion" in a study conducted by the Research Centre for Small and Medium-Sized Businesses at the University of Trier in 2022.

The art of simplicity

All the expertise and components essential to the products are kept in-house and continuously optimized. This applies to the modular systems as well as to the individually manufactured products. The art of simplicity is the guiding principle of product development, and the process from ordering to production should be equally simple. "Our customers need to understand what we do and what we can do for them," says Tobias Doll, Managing Director for Production. Simplicity was also the guideline for the redesign of the MiniTec website. The focus was on ease of use, intuitive operation and short paths to the goal. Thereby it became clear that many customers prefer to configure their products themselves.

Customers want to do the configuration themselves

This desire and the need to optimize internal processes were a perfect match. In their search for a powerful configurator solution, the company found what they were looking for with their CAD supplier: MuM supplies MiniTec with Autodesk Inventor, and the customX software platform from the Limburg-based MuM subsidiary of the same name was an ideal fit with its wide range of features. The set of rules was to be developed in-house after training, and interfaces to existing systems were established in cooperation with the customX development team.

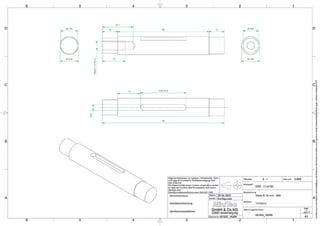

Starting point: shafts

One product group after the other was made available via customX. The start was made with shafts. MiniTec is a specialist for the machining of surface-hardened precision steel shafts used in linear technology. The range of services extends from simple cutting to completely manufactured drive shafts, including all turning, drilling and milling work.

All documents are generated automatically

The new configurator makes ordering via the web really easy: In the first step, the shaft is selected and specified in more detail by the number and type of sections and the material. Then dimensions and properties are defined for each section. Selection menus for some queries ensure that only sensible entries are made and that it is possible to manufacture the shaft. In the 3D preview, the price for the configured shaft is visible. Queries are made at the touch of a button. The customer can then download the STEP file as well as the specification and the production drawing - customX generates the entire documentation in the background in just a few minutes. At the same time, this is also available to MiniTec sales. This procedure saves a lot of time when requesting and preparing quotations, and also in the further processing of the order.

Integration of internal systems

The interfaces to the ERP system and the web store were adapted by customX to MiniTec's requirements. Here, the devil is in the details, as Tobias Doll explains. A lot of coordination and cooperation was required. It was also necessary to consider the security of the overall solution. A door can open too quickly for hackers. Open communication and a lot of coordination work ensured that everything ran correctly. Only after many tests by the field staff were customers allowed to use the configurator. The team then developed the configurator for adjustment units (also linear components). This is now also available on the MiniTec website and is being used intensively.

Digitalization as a success factor

It is already clear that MiniTec is on the right track with customX in terms of process optimization. "Digitalization is a decisive success factor," says Tobias Doll. "If our customers reach their goals faster and at the same time the employees in the design department can work more efficiently, we have done everything right - not least thanks to customX."

If our customers reach their goals faster and at the same time the employees in the design department can work more efficiently, we have done everything right - not least thanks to customX.

Tobias Doll

Managing director production, MiniTec GmbH & Co. KG